With advancements in technology, the field of metal fabrication has seen significant improvements. One of the most notable developments is the introduction of CNC laser tube cutters. These machines have revolutionized the way metal fabrication is done, offering numerous advantages over traditional methods. In this article, we will explore the advantages and applications of CNC laser tube cutters in metal fabrication.

Advantages of CNC Laser Tube Cutters

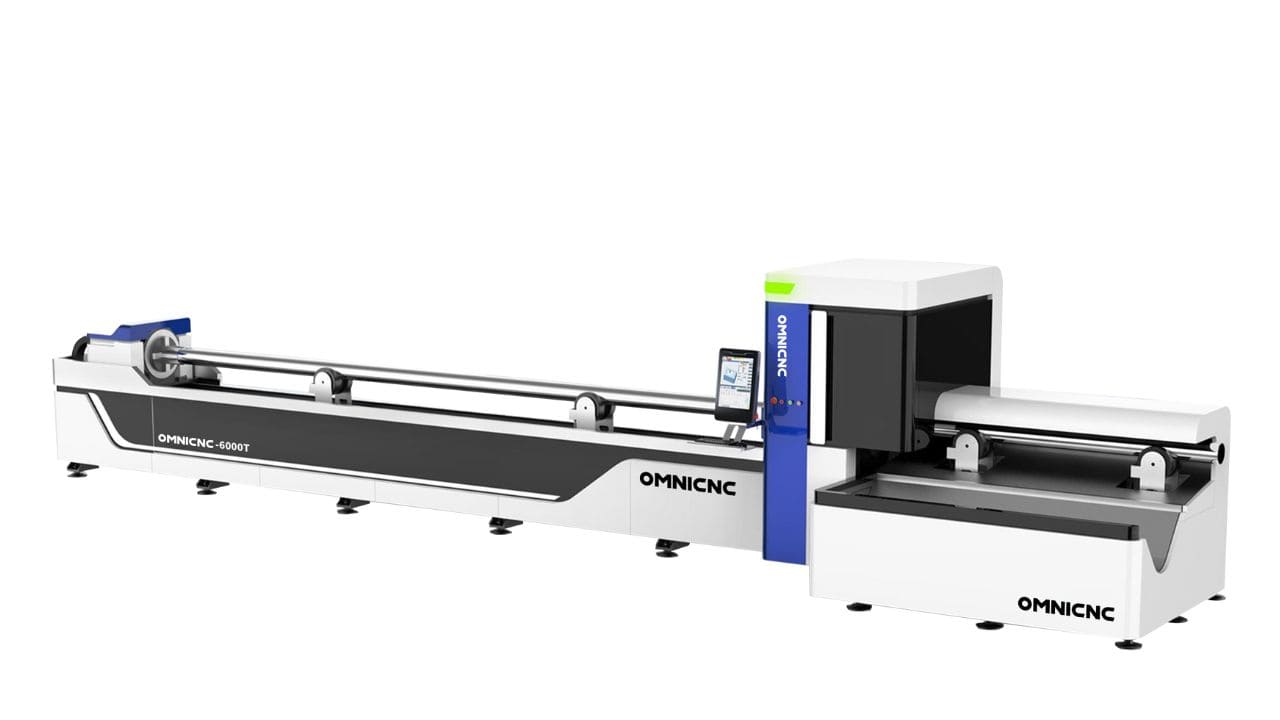

Precision: One of the biggest advantages of CNC laser tube cutters is their ability to achieve high precision cuts. These machines use laser technology to cut through metal with incredible accuracy, allowing for intricate designs and complex shapes. The precision offered by CNC laser tube cutters ensures that each piece is cut exactly as intended, reducing the need for additional finishing or adjustments. CNC tube cutting equipment is a vital tool for precision metal fabrication. It is used to cut metal tubes with high accuracy and speed. It is composed of an automated cutting head, controller, and software.

Conclusion

CNC laser tube cutters have revolutionized the field of metal fabrication. Their precision, speed, versatility, efficiency, and automation make them highly advantageous in various applications. From architectural metalwork to automotive manufacturing, CNC laser tube cutters have become essential tools in the industry. As technology continues to advance, we can expect further improvements in CNC laser tube cutters, making them even more indispensable in metal fabrication.