Polytetrafluoroethylene (PTFE), renowned for its non-stick properties and chemical resistance, has undergone significant advancements through modification processes. Modified PTFE, also known as modPTFE, extends the capabilities of traditional PTFE, making it a versatile material with applications across various industries. This article explores the applications and recent advancements that have propelled modified PTFE to the forefront of innovation.

1. Enhanced Lubrication and Friction Reduction

One of the key advancements in modified PTFE lies in its enhanced lubrication properties. Traditional PTFE is already known for its low friction coefficient, but modifications have taken this attribute to new heights. Industries such as automotive, manufacturing, and aerospace benefit from the reduced wear and improved efficiency that modified PTFE brings to moving parts and machinery.

Image source: Google

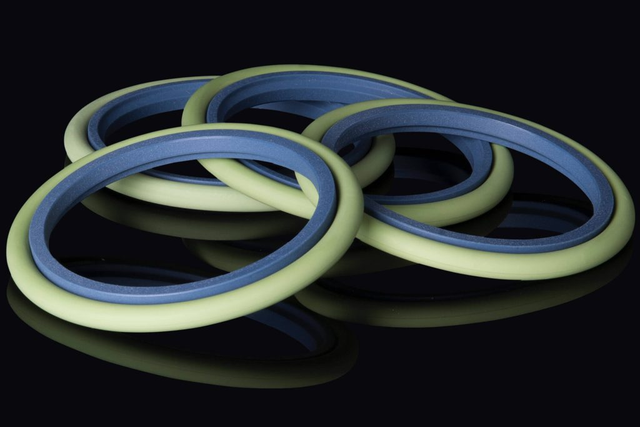

2. Seals and Gaskets in Extreme Environments

Modified PTFE excels in demanding environments where exposure to extreme temperatures, corrosive chemicals, and high pressures is common. This makes it an ideal material for seals and gaskets in industries such as oil and gas, chemical processing, and pharmaceuticals. The modified version's ability to maintain its integrity and sealing properties under harsh conditions sets it apart from conventional materials.

3. Electrical and Insulation Applications

The electrical industry has embraced modified PTFE for its excellent dielectric properties. It serves as an ideal material for insulating cables, connectors, and electronic components. The modified version enhances PTFE's already impressive electrical insulation capabilities, making it a reliable choice in applications where maintaining signal integrity and preventing electrical leakage are critical.

4. Thermal Stability and Heat Resistance

Modified PTFE exhibits exceptional thermal stability and heat resistance, outperforming traditional PTFE in high-temperature applications. This makes it a preferred choice in industries such as aerospace, where components are exposed to extreme temperatures during flight. The material's ability to withstand thermal stress without compromising its structural integrity contributes to its widespread adoption.

5. Medical and Pharmaceutical Innovations

In the medical and pharmaceutical fields, modified PTFE has found applications in various critical areas. Its biocompatibility, resistance to chemical sterilization methods, and low friction make it suitable for medical implants, drug delivery devices, and components in diagnostic equipment. The material's inert nature ensures minimal interaction with biological substances, meeting stringent safety standards.

In summary, the applications and advancements in modified PTFE have positioned it as a material of choice in diverse industries. From improving lubrication to withstanding extreme environments, modified PTFE continues to revolutionize the way industries approach challenges, offering solutions that enhance performance, durability, and safety.